The Virtual Textiles Research Group investigates and develops technology at the forefront of digital textile simulation.

Research Directions

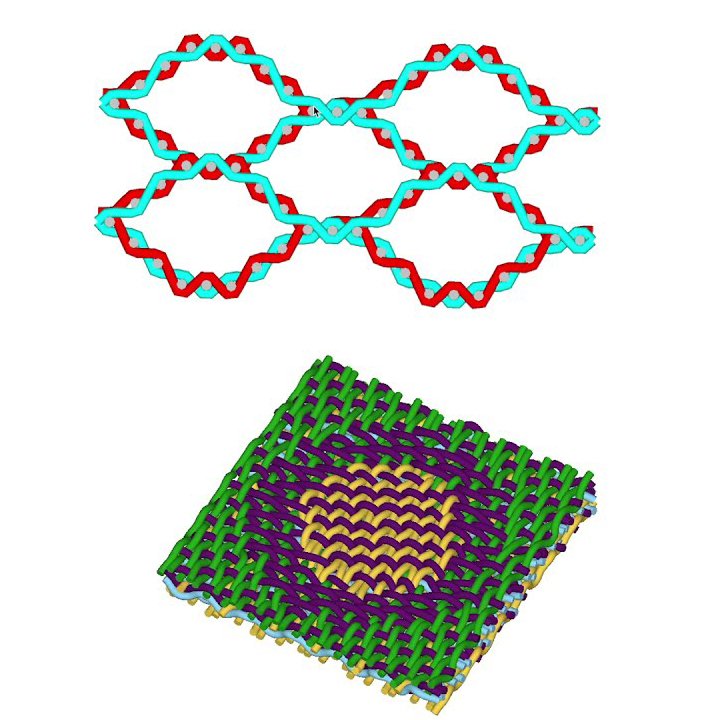

Self-Shaping Textiles

We have developed a workflow for designing self-shaping wovens that gives agency to and aligns with the working practices of textile designers. This includes a process for simulation-assisted drafting, in which textile behaviors can be visualized and iteratively refined in advance of loom setup and fabrication.

Woven Relief

We propose a method to generate 3D weaving patterns for height fields by slicing the shape along intersecting arrays of parallel planes and then computing the paths for all the warp and weft yarns, which travel in these planes. We demonstrate the method by generating weave structures for different shapes and fabricating a number of examples in polyester yarn using a Jacquard loom.

Weavecraft Software

Weavecraft is an interactive, simulation-based design tool for 3D weaving. Unlike existing textile software that uses 2D representation for design patterns, Weavecraft deploys a novel weave block representation that helps the user to understand 3D woven structures and to create complex multi-layered patterns while running interactive local yarn simulation.

Heritage Textiles

The RISD Museum’s Costume & Textile Collection includes many industrially woven textile samples from the late19th Century. We have utilized scanning and visualization technology to better understand how these samples were created and how they might be remade through alterations to existing machines.

3D Weaving

Through industry partnership, we investigate 3D woven textiles of the sort used in ultra-strong composites such as engine fan blades. Predicting yarn behavior related to compression, friction and take-up is key to the successful composition of samples and creates a rich dataset for simulation trials.

Quantum Weaving

Until now, all dimensional weaving executed on rapier or shuttle looms requires sequential line-by-line weft insertion and sequential shed formation. The recent implementation of multi-shuttle looms and servo-driven shedding systems changes this, and creates the need for new design and visualization language.

Virtual Textiles Research Group

Simulated virtual prototypes have revolutionized the design process in most engineering fields, eliminating much trial-and-error and enabling designs to be refined before real prototypes are built. As computational power becomes commonplace, a major emerging application of simulation is to design fields where the aesthetics of appearance, shape, and motion are primary concerns on a par with strength, weight, or efficiency. However, certain classes of materials consistently elude the available tools, and textiles form one of the most important examples.